New Materials Accelerate in Wind Power, Redefining the Load-Bearing Logic of Fasteners

The wind power industry has been changing at a remarkable pace.

From large-scale onshore projects to the full expansion of offshore wind, and now toward deep-sea and floating turbines, wind turbines are becoming taller, larger, and structurally more demanding. Behind these visible changes, one category of components is quietly gaining strategic importance: wind power fasteners.

Once regarded as standard connecting parts, fasteners are now integral to the structural safety of modern wind turbines. They form an invisible load-bearing network that directly affects stability, operational safety, and long-term reliability. As a result, material innovation and system-level performance of wind fasteners have moved to the center of industry discussions.

As Turbines Grow, Fasteners Must Evolve

With 8MW and 10MW turbines becoming mainstream and 16MW offshore models entering large-scale deployment, structural loads on connection systems are increasing dramatically. In offshore environments, the challenge intensifies. Salt spray, humidity, constant vibration, and complex cyclic loads place extreme demands on bolt strength, toughness, fatigue resistance, and corrosion protection.

Industry experts often point out that in large wind turbines, the smallest components may carry the greatest responsibility. Fasteners are no longer simple connectors; they are critical safety units within the system architecture. Design priorities have shifted toward long-term preload stability, friction consistency, and full lifecycle reliability.

Materials Take Center Stage

Against this backdrop, material innovation has become the primary battleground for wind fastener development.

High-strength alloy steels continue to advance, lightweight solutions are being explored, and corrosion-resistant coatings and surface treatments are seeing rapid improvement. Manufacturers now focus less on isolated performance metrics and more on stability under real operating conditions.

OEMs are also raising their expectations. Beyond price and delivery, they increasingly value suppliers’ capabilities in material research, testing validation, and batch consistency. As a result, fastener manufacturers are transitioning from component suppliers to active participants in engineering solutions.

Domestic Fasteners Secure Key Positions

These changes are already visible in practice.

In critical applications such as main flanges, tower connections, and yaw systems, a group of domestic manufacturers has accumulated solid engineering experience. Companies such as Zhejiang Dite High-Strength Bolts Co., Ltd. and Hangte Hardware (Zhejiang) Co., Ltd. have continuously invested in large-diameter, high-strength bolts. Through improved microstructure control, stable heat treatment processes, and friction consistency management, their products are increasingly adopted in demanding wind power projects.

By addressing challenges posed by offshore environments—high salinity, humidity, and dynamic loads—these companies have advanced corrosion-resistant technologies, introduced intelligent inspection systems, and upgraded automated production lines. Domestic high-end wind fasteners are steadily moving toward higher strength, lower weight, and longer service life.

A Platform for Industry Dialogue

Technological progress also requires effective communication platforms.

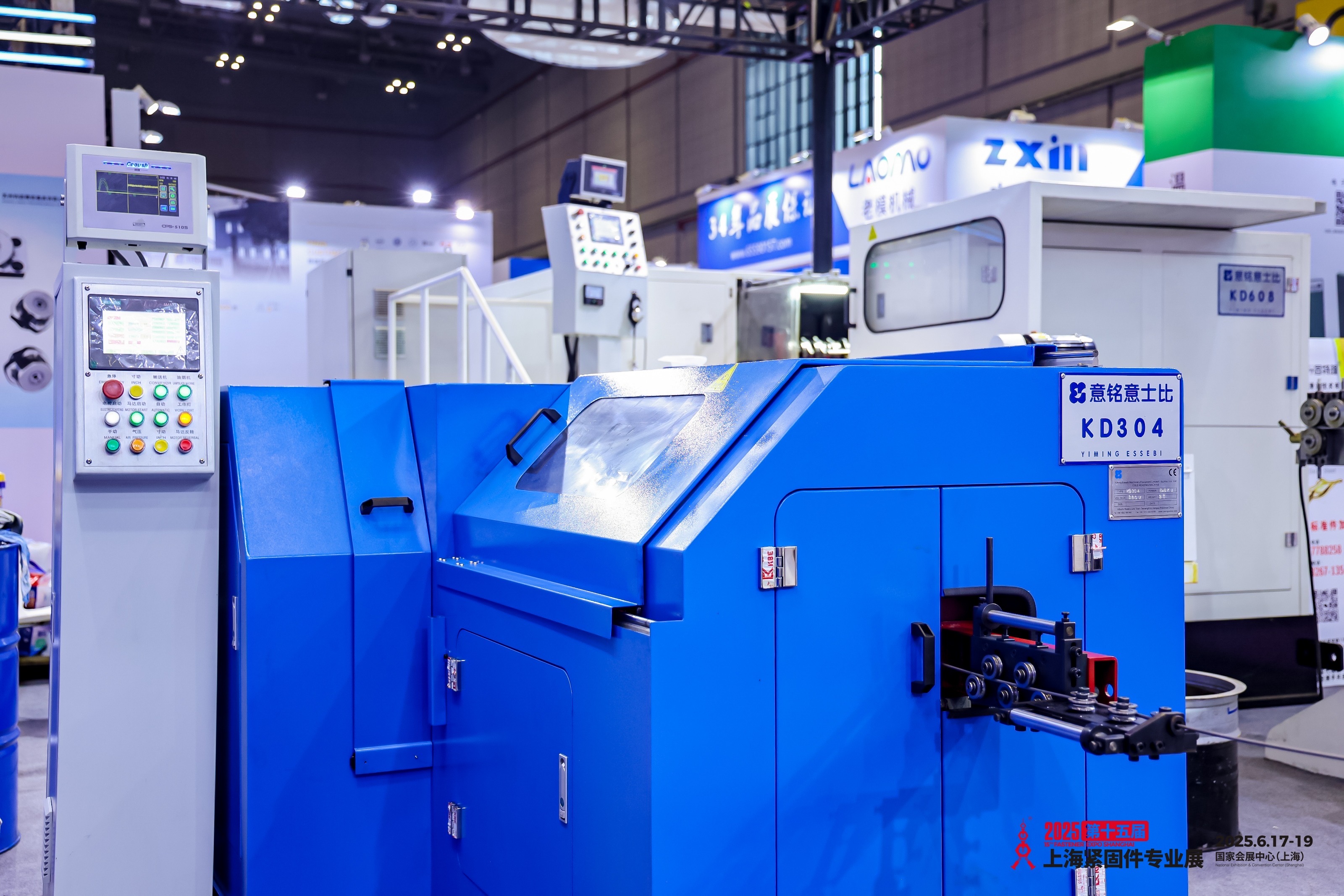

Fastener Expo Shanghai 2026 will take place from June 24 to 26 at the National Exhibition and Convention Center (Shanghai). The exhibition will feature a dedicated wind power sector, showcasing the latest developments in materials, manufacturing processes, testing technologies, and engineering applications for wind fasteners.

During the event, industry participants will present emerging material trends, discuss import-substitution solutions, and interpret new safety requirements from turbine manufacturers. OEMs, tower producers, blade manufacturers, and offshore engineering companies will also engage in forums, technical sessions, and supply-demand matchmaking activities.

For many fastener companies, this represents both a showcase and a gateway to high-end wind power applications.

Small Components, Strategic Impact

Ultimately, innovation in wind fastener materials extends beyond a niche technical upgrade. It is closely tied to the broader goal of industrial self-reliance in high-end equipment manufacturing.

While large, ultra-high-strength wind fasteners were once heavily dependent on imports, improvements in domestic material science, heat treatment, simulation testing, and quality control are enabling Chinese manufacturers to enter global OEM supply chains.

Looking ahead to deep-sea and floating wind power, lightweight materials, composite reinforcement, and intelligent preload and health monitoring systems are likely to define the next stage of development. Fasteners may remain small and unobtrusive, but their role in ensuring turbine reliability will only continue to grow.

As wind turbines push further into extreme operating conditions, connection reliability becomes a prerequisite for performance improvement. Fastener Expo Shanghai 2026 will continue to provide a practical and open platform to support this evolution.

After fifteen consecutive editions, the Fastener Expo Shanghai (FES) has developed into one of the “three major global fastener trade shows.” Its exhibitors, product quality, event content, the number of domestic and international visitors, and on-site transaction volume all set industry benchmarks. In 2025, the expo further became the largest fastener exhibition in the world in terms of exhibition area.

Official Website: www.fastenerexpo.cn/en

Media Contact: Goblic Hu

Email: goblic.hu@ebseek.com

Phone: +86 138 1631 0340

Please first Loginlater ~