eVTOL Drives Next-Generation Lightweight Fasteners: Five Core Trends Shaping the Industry

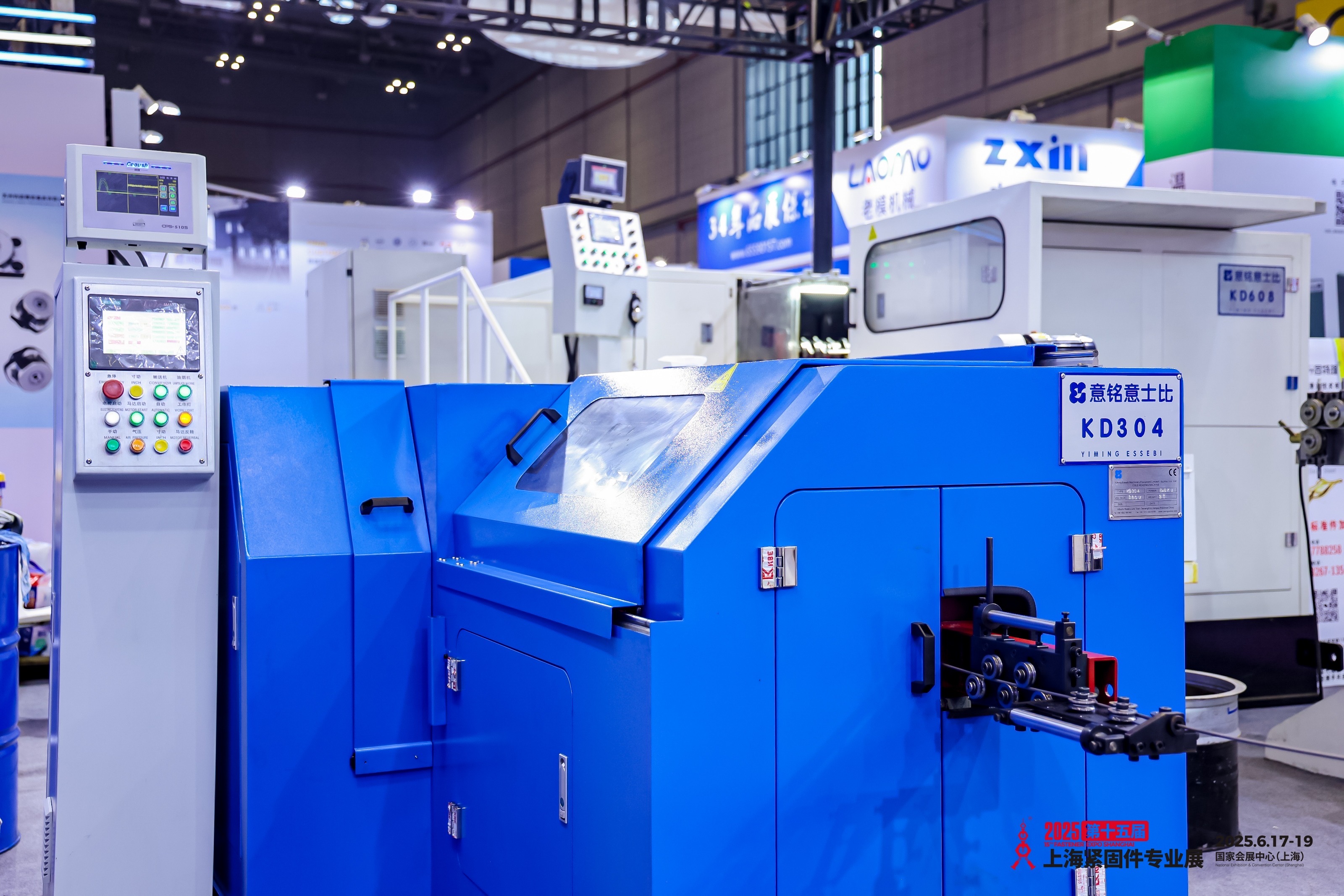

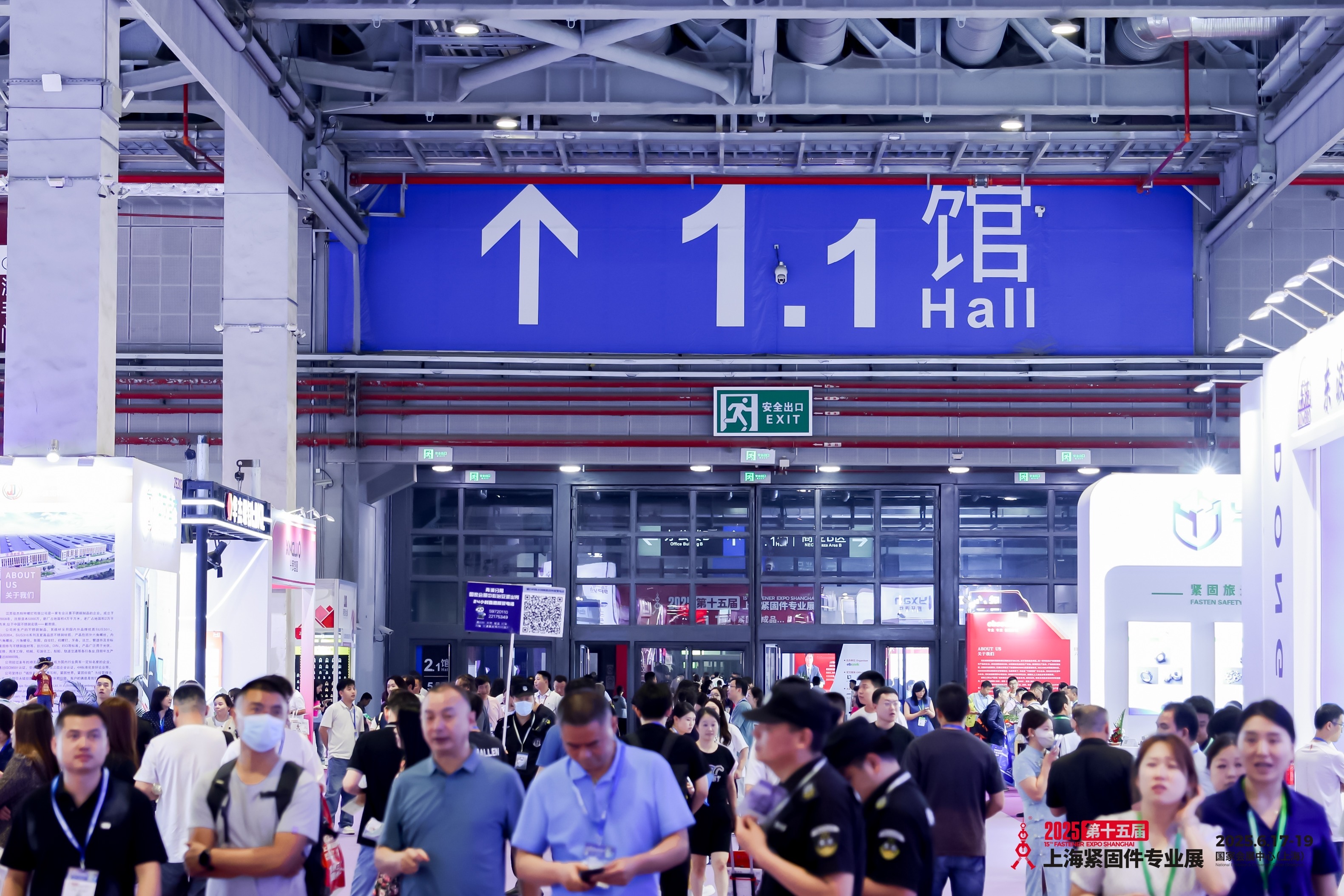

The Fastener Expo Shanghai 2026 (24–26, 2026) at the National Exhibition and Convention Center (Shanghai) will feature 70,000㎡ of exhibition space, 1,400+ exhibitors, and over 25,000 professional visitors. This year, the expo will launch the FJ Fastening & Connection Conference and the Urban Air Mobility Fastening & Assembly Forum, highlighting eVTOL, electric aviation, lightweight structures, and advanced materials.

As low-altitude aviation enters strategic growth plans across multiple regions, eVTOL (electric vertical takeoff and landing aircraft) is becoming a critical urban mobility solution. Unlike traditional aviation or ground transport, eVTOL imposes unprecedented demands on fasteners in terms of weight, structural reliability, fatigue life, vibration resistance, and safety redundancy. Five core trends are driving innovation in the fastener sector:

- Extreme Lightweight & High Strength: Carbon-fiber composites require titanium, high-strength aluminum, and composite-specific fasteners to achieve weight reduction without compromising strength, corrosion resistance, or longevity.

- Cross-Material Interface Compatibility: Fasteners must bridge composites and metals with differing moduli and thermal expansion, using optimized head designs, precise rolling, anti-loosening structures, and advanced coatings.

- Enhanced Vibration & Fatigue Resistance: eVTOL rotor systems generate high-frequency vibration, requiring fasteners with multi-fold fatigue life and stable preload under complex conditions including temperature, humidity, and cyclic loads.

- Certification-Driven Safety: Commercial eVTOL operations demand strict airworthiness compliance, including material traceability, batch consistency, fatigue and corrosion testing, and assembly reliability.

- Automated & Digital Assembly: High-volume, aviation-grade production requires fasteners compatible with automated torque equipment, intelligent inspection systems, and digital lifecycle management for traceability and performance monitoring.

Leading domestic companies are already advancing along these directions. Leng Shui Jiang Tian Industrial Co., Ltd evelops lightweight titanium and composite fasteners with consistent high-precision forming processes, while Jingjiang Feitian Fastener Manufacturing Co., Ltd specializes in anti-loosening designs and fatigue optimization for high-vibration applications. Both represent China’s move toward aviation-grade, lightweight, and intelligent fastening solutions for the low-altitude economy.

With policy support, investment, and technological innovation driving the sector, eVTOL and the broader low-altitude economy represent a trillion-yuan growth opportunity. Fasteners are the essential foundation ensuring structural integrity, vibration resilience, fatigue performance, and airworthiness. Fastener Expo Shanghai 2026 will bring industry innovation, application insights, and supply-chain connectivity to a single platform, enabling participants to explore the future of urban air mobility and position China’s fastening industry at the forefront of global competition.

Official Website: www.fastenerexpo.cn/en

Media Contact: Goblic Hu

Email: goblic.hu@ebseek.com

Phone: +86 138 1631 0340

Please first Loginlater ~