From Price Competition to Material Competition: Raw Material Upgrades Are Reshaping the Fastener Industry

Amid ongoing adjustments in the global manufacturing landscape and rising supply chain uncertainties, the fastener industry is undergoing a fundamental shift. Competition is gradually moving away from price-driven cost battles toward a stronger focus on material performance, consistency, and process compatibility. What was once a race to the lowest price is increasingly becoming a competition centered on materials.

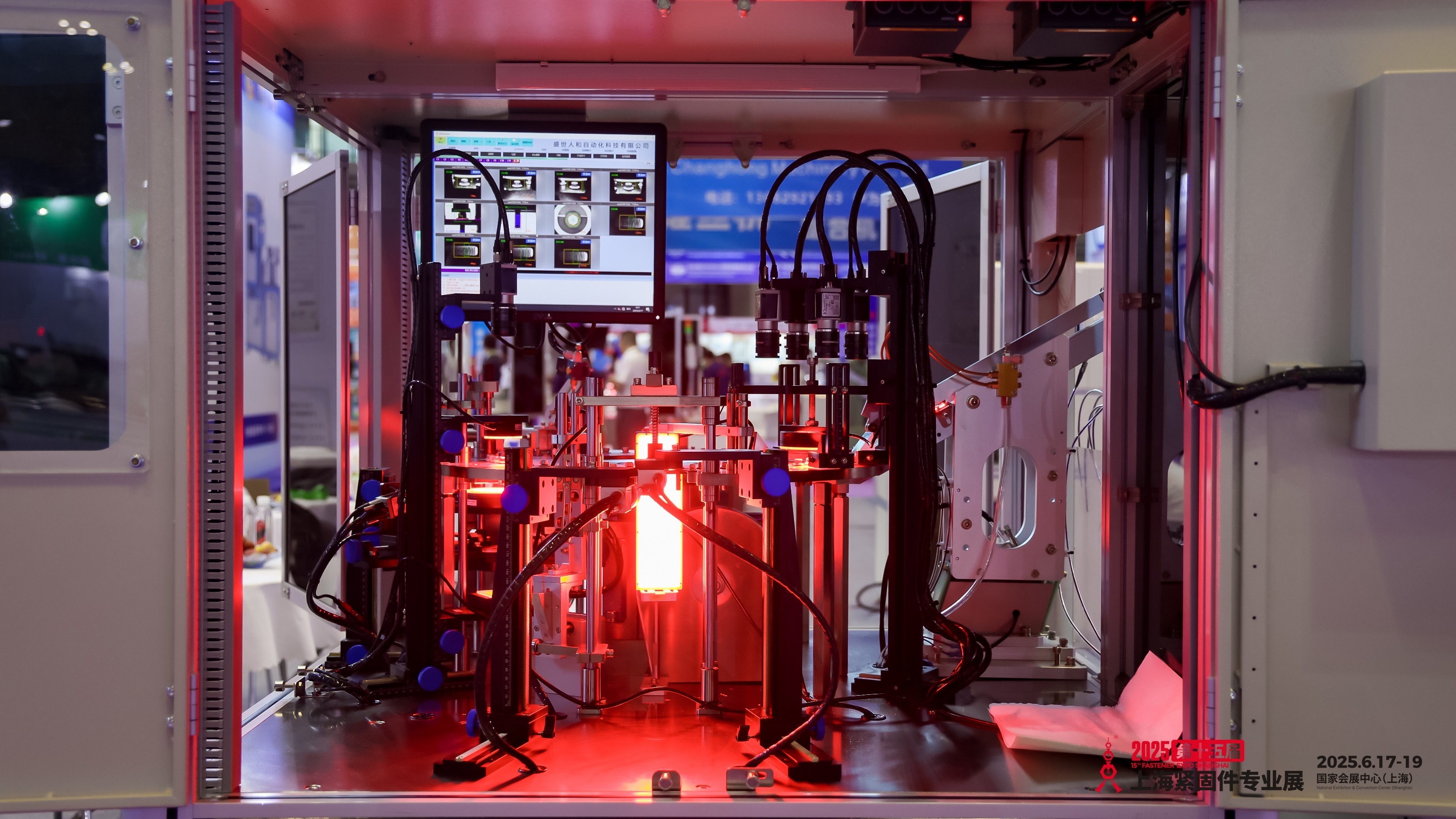

As one of the most critical upstream elements in fastener production, wire rod and raw materials are being re-evaluated across the industry. Against this backdrop, Fastener Expo Shanghai 2026 will take place on June 24–26, 2026, at the National Exhibition and Convention Center (Shanghai). The exhibition will continue to highlight wire rod and raw materials, providing a platform for technical exchange and industry dialogue aimed at redefining the value of materials within the fastener supply chain.

Historically, wire rod and raw materials were viewed primarily as cost factors. Steel price fluctuations and procurement timing directly influenced pricing strategies and order competitiveness. While this price-centric approach once dominated the market, rising demands from downstream applications have exposed its limitations. Increasingly, manufacturers recognize that price competition alone is no longer sufficient to ensure sustainable growth.

In practice, raw materials play a decisive role in manufacturing stability. Chemical composition consistency, microstructure uniformity, surface quality, and inclusion control all have a significant impact on cold heading, thread rolling, and heat treatment processes. Excessive material variation often leads to reduced production speeds, frequent adjustments, or lower yields—hidden costs that are becoming more prominent as labor, energy, and equipment expenses continue to rise.

At the same time, downstream industries such as automotive, new energy equipment, and heavy machinery are redefining fastener requirements. The benchmark has shifted from basic functionality to long-term reliability and batch consistency. In these applications, the cost of failure far outweighs minor differences in unit price, making material stability and controllability critical considerations.

Material upgrading does not simply mean selecting higher-grade or more expensive steel. Instead, it involves a systematic approach centered on compatibility and consistency. From material selection through data-driven process control, manufacturers are increasingly quantifying the relationship between raw material performance, production efficiency, and final product quality. This shift transforms raw materials from passive inputs into actively managed production variables.

Industry practices already reflect this transition. AOZHAN Industrial Co., Ltd. has strengthened its focus on wire rod consistency, optimizing material selection to better match its manufacturing processes and reduce production variability. In the automotive fastener sector, Shanghai Yixuan Automotive Fasteners Co., Ltd. has incorporated raw material stability into the front end of its quality control system to meet increasingly stringent OEM requirements. These examples demonstrate that material-focused strategies are long-term investments closely tied to manufacturing capability upgrades.

From a broader perspective, material upgrades are also reshaping supply chain relationships. Wire rod suppliers are increasingly involved in technical collaboration, while fastener manufacturers provide feedback that drives further material optimization. This performance-driven cooperation is gradually replacing purely transactional relationships with deeper technical partnerships.

Against this backdrop, structured communication around wire rod and raw materials has become increasingly important. As one of the world’s leading professional platforms for the fastener industry, Fastener Expo Shanghai continues to focus on fundamental supply chain dynamics, showcasing the interconnection between materials, manufacturing processes, and application demands. After 15 successful editions, the exhibition has grown into one of the three largest fastener trade fairs globally, becoming the world’s largest fastener exhibition by floor area in 2025.

As manufacturing logic evolves, raw materials are no longer just the starting point of cost negotiations, but a foundation influencing production efficiency, quality stability, and customer trust. The shift from price competition to material competition reflects a rational and necessary response to industry realities. Through a deeper understanding of material value, the fastener industry is steadily building a more resilient and sustainable competitive framework.

Benefiting from the rapid development of China’s fastener industry in recent years and the growing sourcing demand from international buyers, Fastener Expo Shanghai has established itself as one of the world’s three leading fastener exhibitions, alongside Fastener Fair Global (Stuttgart, Germany) and the International Fastener Expo (USA). In 2025, with an actual exhibition area of 65,000 square meters, Fastener Expo Shanghai became the largest professional fastener exhibition in the world by exhibition scale.

Official Website: www.fastenerexpo.cn/en

Media Contact: Goblic Hu

Email: goblic.hu@ebseek.com

Phone: +86 138 1631 0340

Please first Loginlater ~