From Raw Material to Finished Product: A Panorama of Core Equipment in the Fastener Industry

With the global manufacturing sector moving rapidly toward high-end, intelligent and green production, demand for fasteners continues to grow in automotive, new energy, rail transit and advanced manufacturing industries. Known as the “rice of industry,” fasteners may be small, but they play a critical role in structural integrity and safety. Their production relies heavily on advanced equipment and systematic processes. The industry is now entering a key stage of equipment renewal and smart manufacturing transformation.

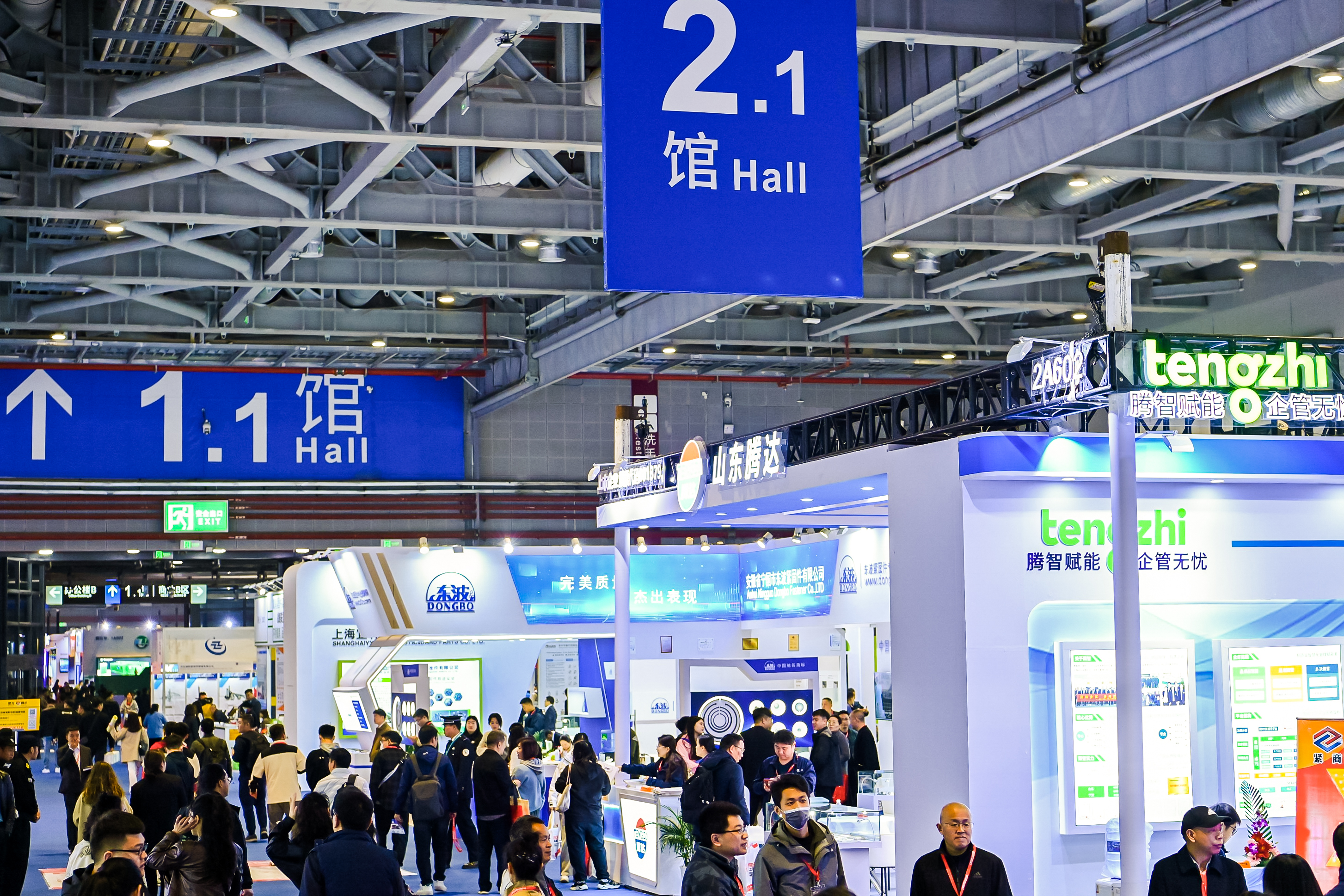

Fastener Expo Shanghai 2026 will be held from June 24–26, 2026 at the National Exhibition and Convention Center (Shanghai). The show will focus on the latest developments in fastener manufacturing machinery and intelligent equipment, presenting a full-chain panorama from raw material processing to finished products and providing a high-level platform for global buyers, manufacturers and technology providers.

Core Equipment: Cold Heading Machines Define Capacity

Cold heading machines are the first critical step in fastener production. They form bolts, screws and nuts directly from steel wire at room temperature through plastic deformation. Modern multi-station cold heading machines integrate automatic feeding, die sets and high-pressure punches, completing multiple operations in a single setup with high efficiency and consistency.

Industry data shows that production lines equipped with multi-station cold heading machines can improve efficiency by 30–50% and achieve material utilization rates above 95%, making them a key indicator of a company’s scale and automation level.

Key Supporting Equipment Builds a Complete Process Chain

Beyond cold heading, a series of essential machines work together to complete fastener production. Wire drawing machines prepare steel wire to the required diameter and strength; thread rolling machines use cold forming to improve thread strength and surface quality; tapping machines ensure precise internal threads, with accuracy requirements reaching ±0.02 mm in automotive, rail and aerospace applications.

In addition, bolt formers, rivet machines, washer equipment, automatic feeding systems, sorting and packaging machines form a complete system from rough processing to finishing. Automated assembly lines significantly enhance efficiency and stabilize shipment pass rates at over 99.5%.

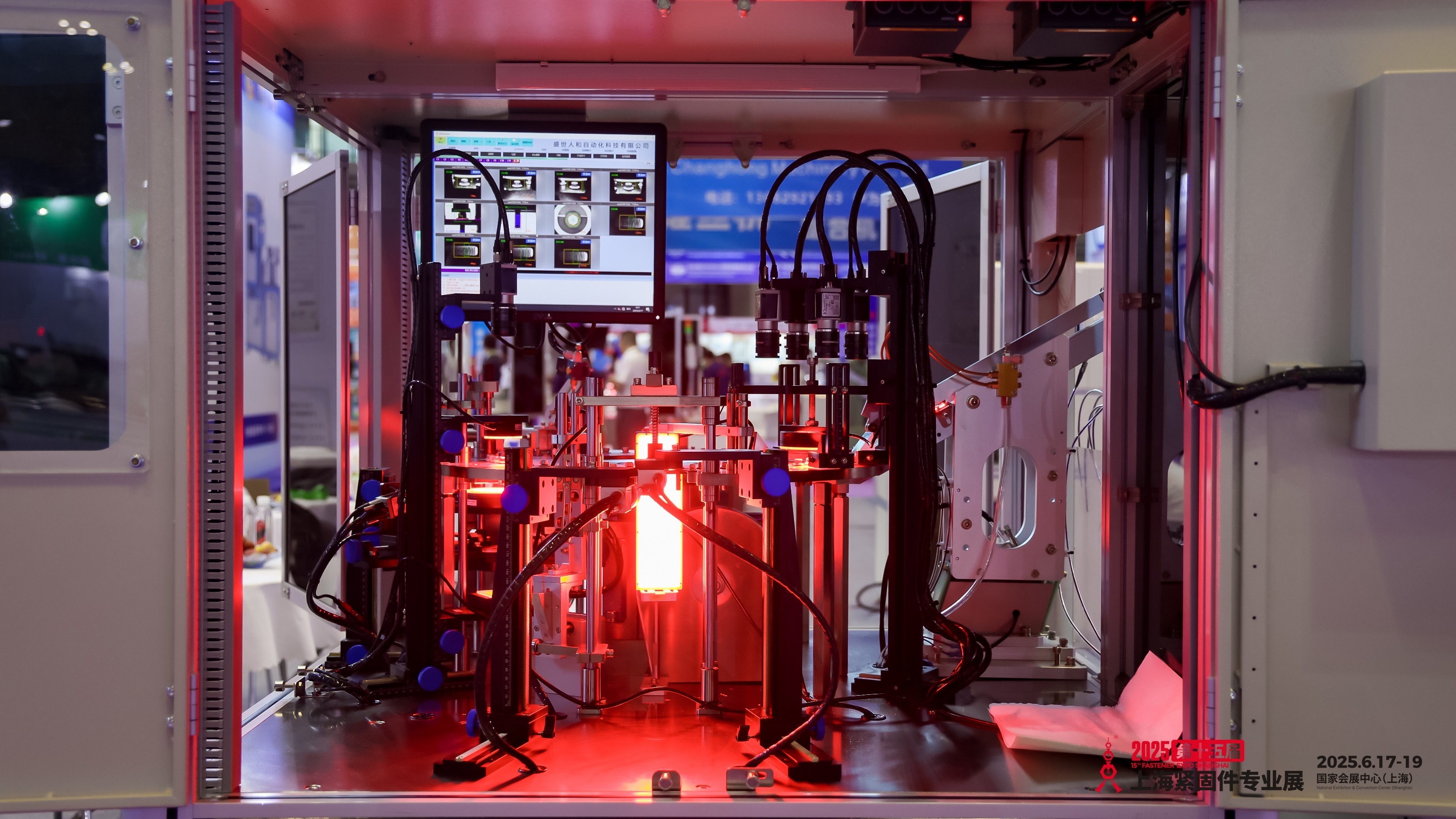

Inspection Equipment Ensures Reliability

In high-reliability sectors such as automotive, rail transit and aerospace, fasteners must undergo strict dimensional, mechanical and non-destructive testing. Online vision inspection, laser measurement and flaw detection systems monitor quality throughout production, effectively reducing rework. Currently, about 65% of China’s high-end fastener production lines are equipped with automated online inspection systems, with even higher penetration in auto parts and wind power industries.

Smart Manufacturing Drives Equipment Upgrades

For manufacturers, upgrading equipment is no longer about single-machine performance alone, but about restructuring the entire manufacturing system. High-efficiency, precise and intelligent equipment shortens lead times, reduces costs and enhances data traceability. Equipment suppliers are now helping traditional lines transform toward digital and smart manufacturing through automatic feeding, online inspection and integrated assembly solutions.

Fastener Expo Shanghai: A Global Industry Benchmark

After fifteen editions, Fastener Expo Shanghai has become one of the world’s three leading fastener exhibitions, and in 2025 it was the largest fastener show globally by scale. Fastener Expo Shanghai 2026 will gather leading equipment manufacturers worldwide, showcasing full solutions from raw material to finished product through live demonstrations, technical forums and equipment displays.

Over the next five years, industry investment will shift from single-machine performance to overall production line optimization and intelligent manufacturing. This exhibition will serve as a key window to present these technologies and trends.

As end-user demand becomes more diversified and the market for high-performance fasteners expands, progress in equipment technology will be the decisive factor for long-term competitiveness. Fastener Expo Shanghai is not only a showcase of the latest equipment, but also a hub for production line upgrading and international cooperation across the global fastener industry.

Exhibition Info:

Fastener Expo Shanghai 2026

Date: June 24–26, 2026

Venue: National Exhibition and Convention Center (Shanghai)

Scale: 70,000㎡, 1,400+ exhibitors, 25,000+ professional visitors

Official Website: www.fastenerexpo.cn/en

Media Contact: Goblic Hu

Email: goblic.hu@ebseek.com

Phone: +86 138 1631 0340

Please first Loginlater ~