A Small Stainless Steel Bolt, Holding Up the Weather-Resistant Future of Solar Mounts

As China’s solar installation capacity climbs rapidly, solar mounting systems act as the backbone of every PV plant, supporting and securing panels with stability that determines the life of the station. Behind this structure, the humble stainless steel bolt plays a pivotal role. One loose or corroded bolt can shift hundreds of panels, even compromise the entire system. With solar projects moving to coastal, desert, and high-altitude regions, the industry faces a crucial question: how can a bolt endure harsh conditions and keep a solar structure standing for two decades?

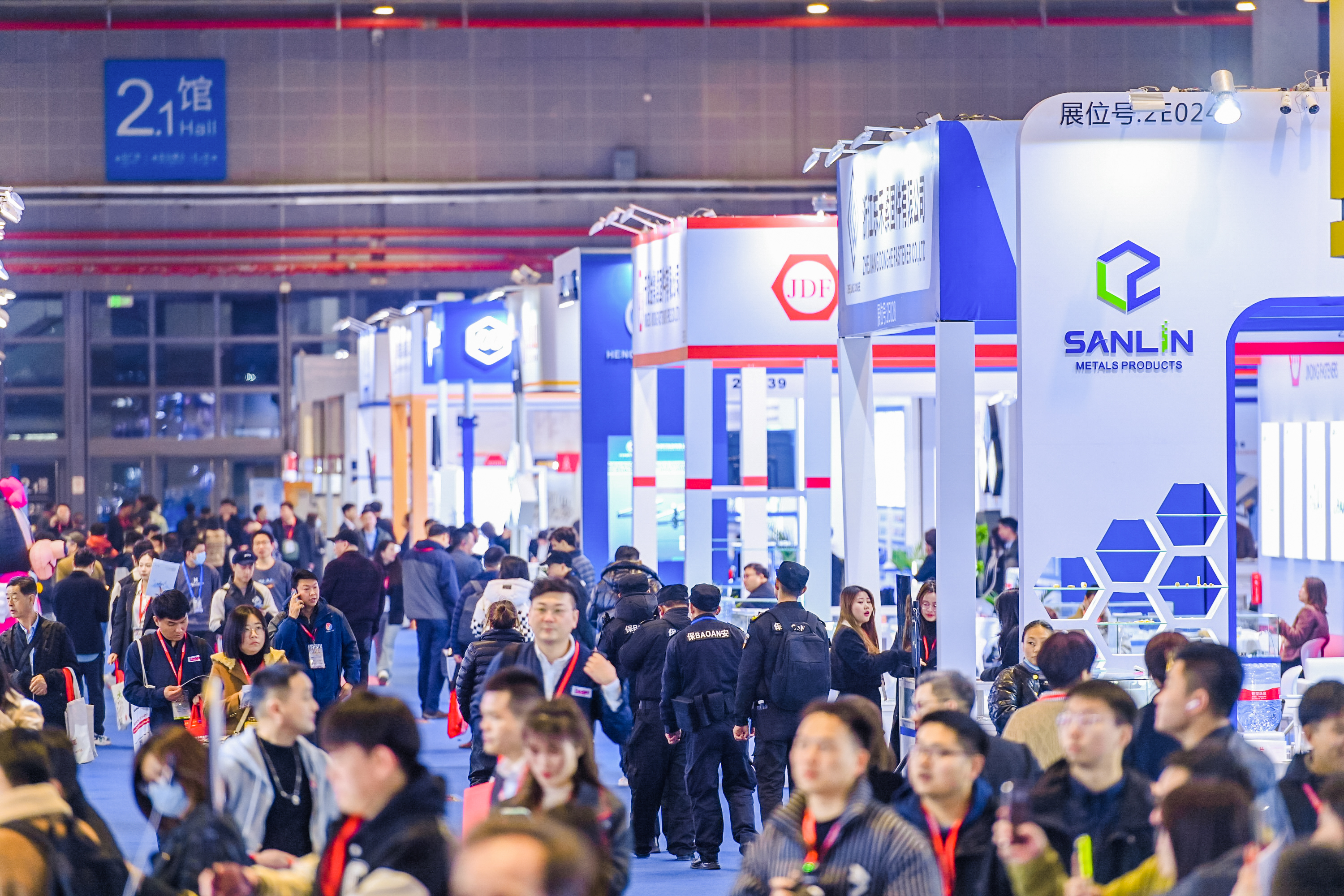

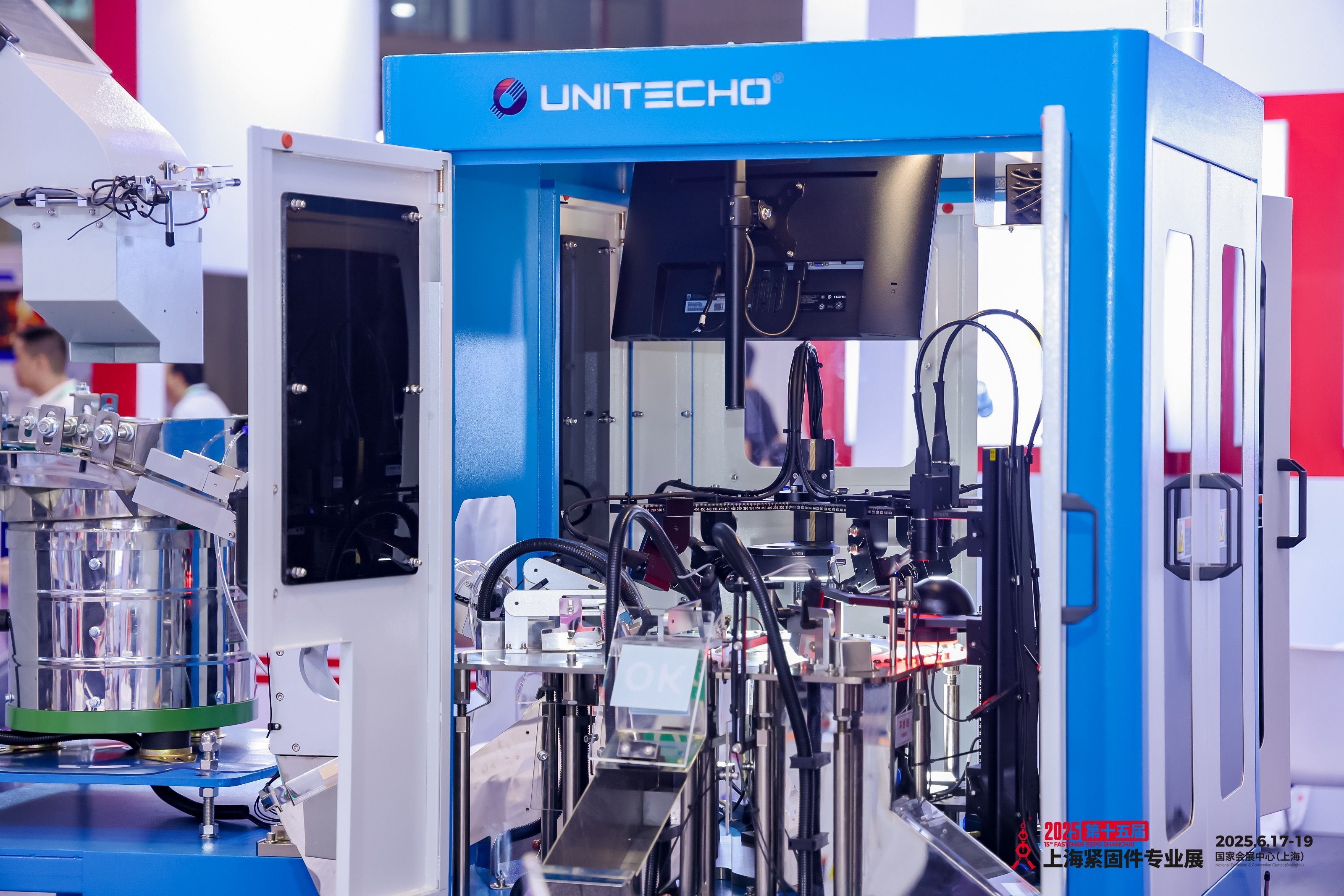

This challenge is a key focus of Fastener Expo Shanghai 2026, scheduled for June 24–26 at the National Exhibition and Convention Center (Shanghai). The expo will feature a dedicated “PV Fastening Technology & Weather-Resistance Innovation” zone, bringing together PV structure firms, material suppliers, and testing organizations to explore breakthroughs for high-corrosion, high-fatigue applications. Attendees will witness weather-resistance simulation rigs and salt spray aging samples, making invisible reliability tangible.

PV plants face more complex corrosion risks than typical industrial structures. Prolonged exposure to sunlight, salt spray, humidity, and dust can trigger galvanic effects, pitting, and fatigue cracks over repeated cycles. In some coastal plants, bolt corrosion exceeds 20% within three years, directly affecting panel angles and structural stability. The solution is not merely “using more expensive steel,” but optimizing materials, processes, and protective measures across the full supply chain.

Material innovation lies at the heart of this effort. Stainless steel’s oxidation resistance, corrosion resistance, and mechanical strength make it ideal. A2-70 (304) suits inland and mild climates, balancing economy and workability. A4-80 (316), with molybdenum, resists chloride environments, ideal for coastal projects. For offshore solar, salt lake plants, or chemical parks, duplex stainless steel 2205 offers a balanced combination of strength, toughness, and corrosion resistance. This progression from 304 to 316 to 2205 illustrates the technical path for weather-resistant solar mounts.

Yet, real micro-innovations emerge in process and management. GOODFIX & FIXDEX GROUP, for instance, employs automated inspection and digital process control to precisely manage coating thickness and uniformity, offering region-specific anti-corrosion solutions. Their R&D team notes that 80% of a bolt’s protection relies on surface treatment details rather than the material alone.

Verification systems matter just as much. Salt spray (ASTM B117), humidity cycle, and fatigue tests are standard measures for assessing weather resistance. Some labs use environmental chambers to monitor corrosion under varying temperature, humidity, and load conditions, providing data for product improvement. FES 2026 will showcase these accelerated aging and real-time monitoring technologies, offering participants a tangible understanding of “weather resistance” in engineering terms.

Economically, while high-grade stainless steel or advanced anti-corrosion technologies require higher initial investment, they reduce lifecycle costs. PV operators report that switching to 316 bolts from galvanized ones lowered maintenance costs by 35% over five years and extended replacement cycles by over three years—significant savings for hundred-megawatt plants.

From material upgrades to system integration, from passive corrosion protection to active weather resistance, the PV mounting industry is quietly evolving. In the coming years, visitors will encounter not just bolts or steel plates, but comprehensive, system-level solutions for extreme environments. These small details are quietly powering a more stable, greener, and longer-lasting energy future.

After fifteen consecutive editions, the Fastener Expo Shanghai (FES) has developed into one of the “three major global fastener trade shows.” Its exhibitors, product quality, event content, the number of domestic and international visitors, and on-site transaction volume all set industry benchmarks. In 2025, the expo further became the largest fastener exhibition in the world in terms of exhibition area.

Official Website: www.fastenerexpo.cn/en

Media Contact: Goblic Hu

Email: goblic.hu@ebseek.com

Phone: +86 138 1631 0340

Please first Loginlater ~