How Can Fasteners Support the Low-Carbon Transformation of Manufacturing?

As the global manufacturing sector accelerates its transition toward greener and lower-carbon development, the basic components industry is facing a new set of challenges and opportunities. As one of the most widely used and highest-volume industrial components, fasteners may be small in size, but they play a critical role across key sectors such as automotive, machinery, construction, energy, and advanced equipment manufacturing. Their production processes, material selection, and application efficiency have a significant and long-term impact on overall carbon emissions throughout the manufacturing value chain.

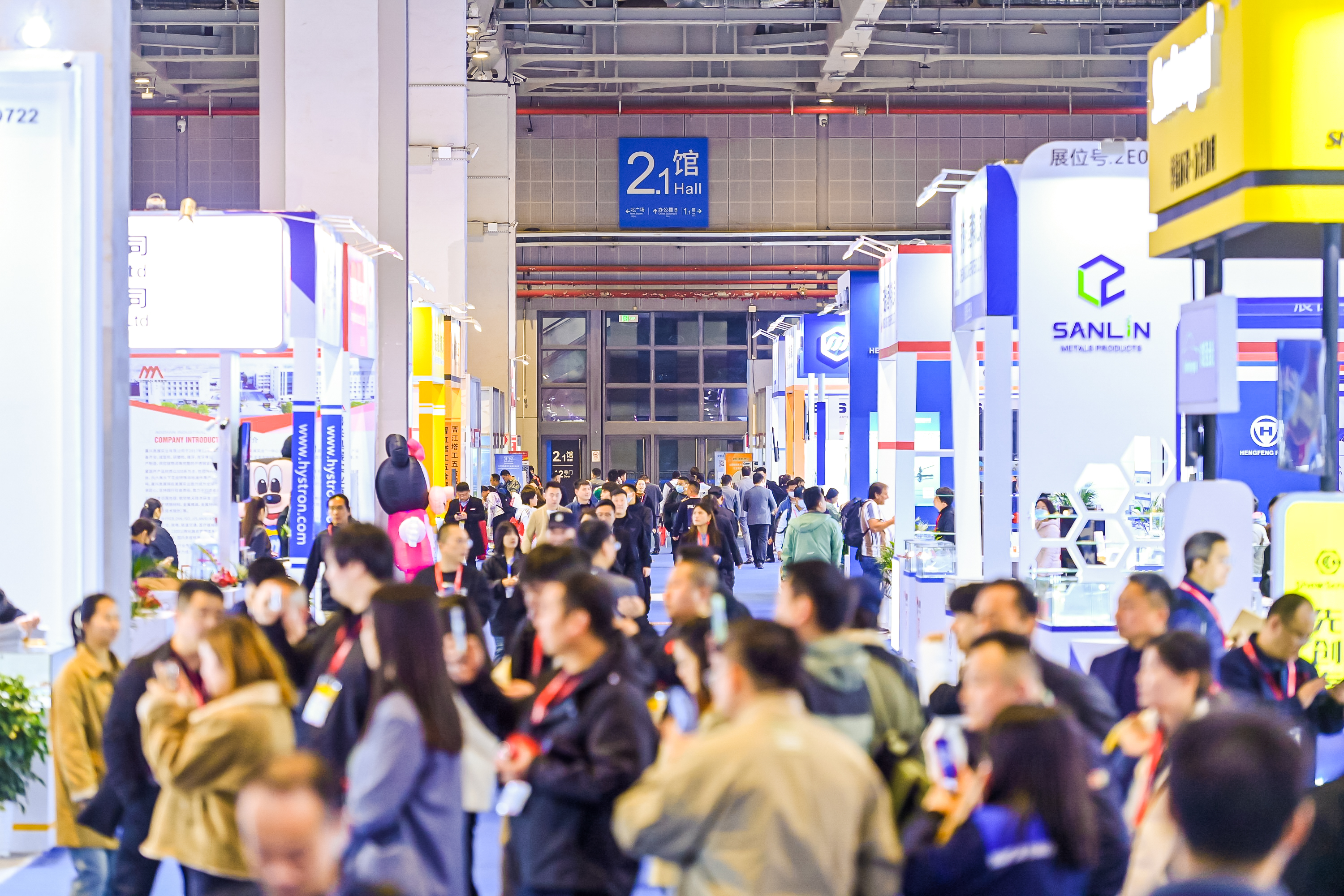

Against this backdrop, the 16th Fastener Expo Shanghai (Fastener Expo Shanghai 2026) will take place from June 24–26, 2026, at the National Exhibition and Convention Center (Shanghai). The event will bring together fastener manufacturers, material suppliers, and technical service providers from around the world to showcase green transformation practices across the fastener industry chain and explore the practical role of basic components in the manufacturing sector’s low-carbon revolution.、

Historically, the fastener industry has often been regarded as energy-intensive, with carbon emissions concentrated in raw material smelting, forming processes, surface treatment, and logistics. However, as carbon accounting, environmental compliance, and supply chain transparency become increasingly important in global manufacturing, fasteners are no longer evaluated solely on strength and dimensional standards. Instead, they are now incorporated into full life-cycle assessments of complete products and engineering projects—prompting fastener manufacturers to reassess their role in the low-carbon transition.

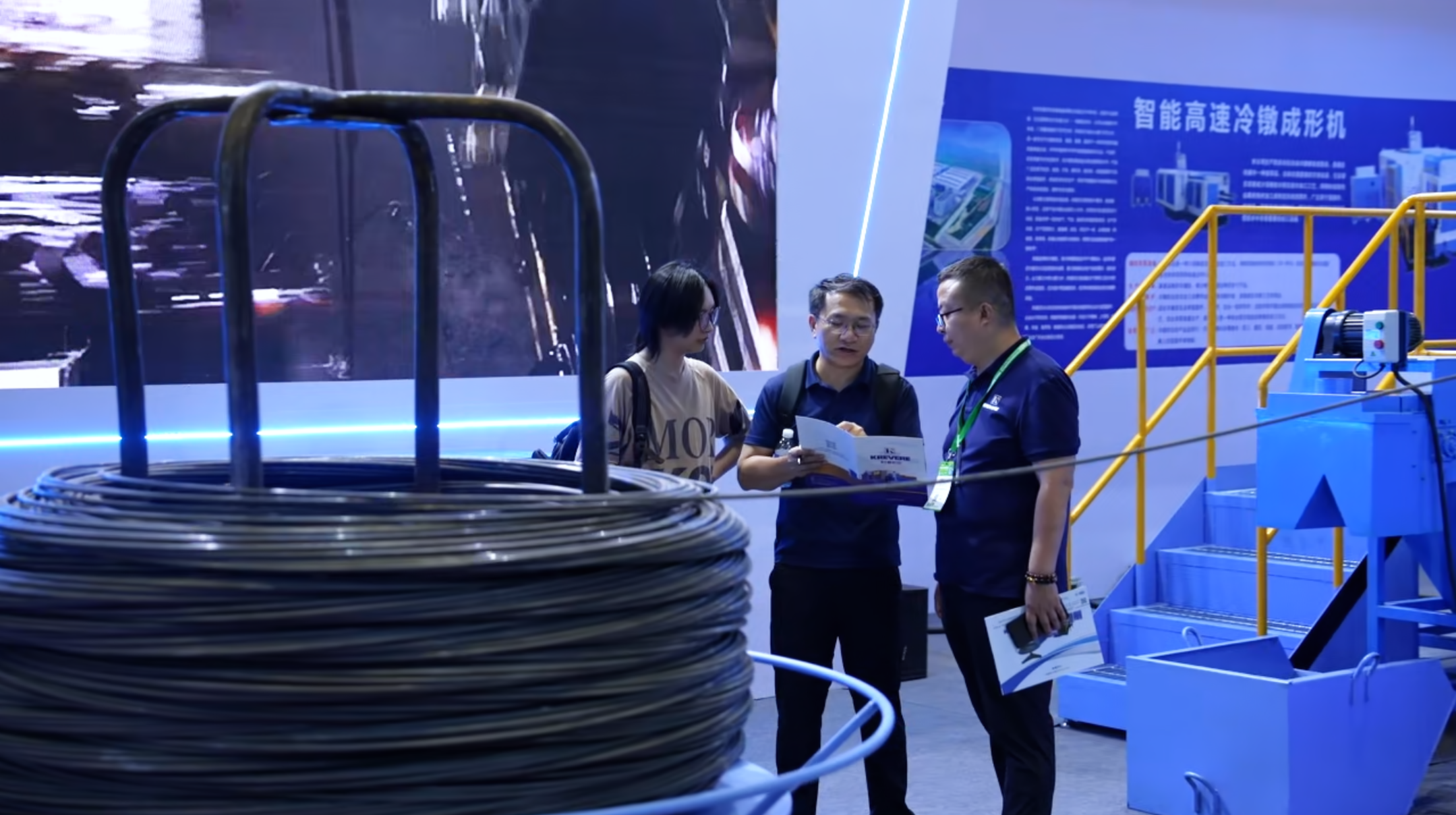

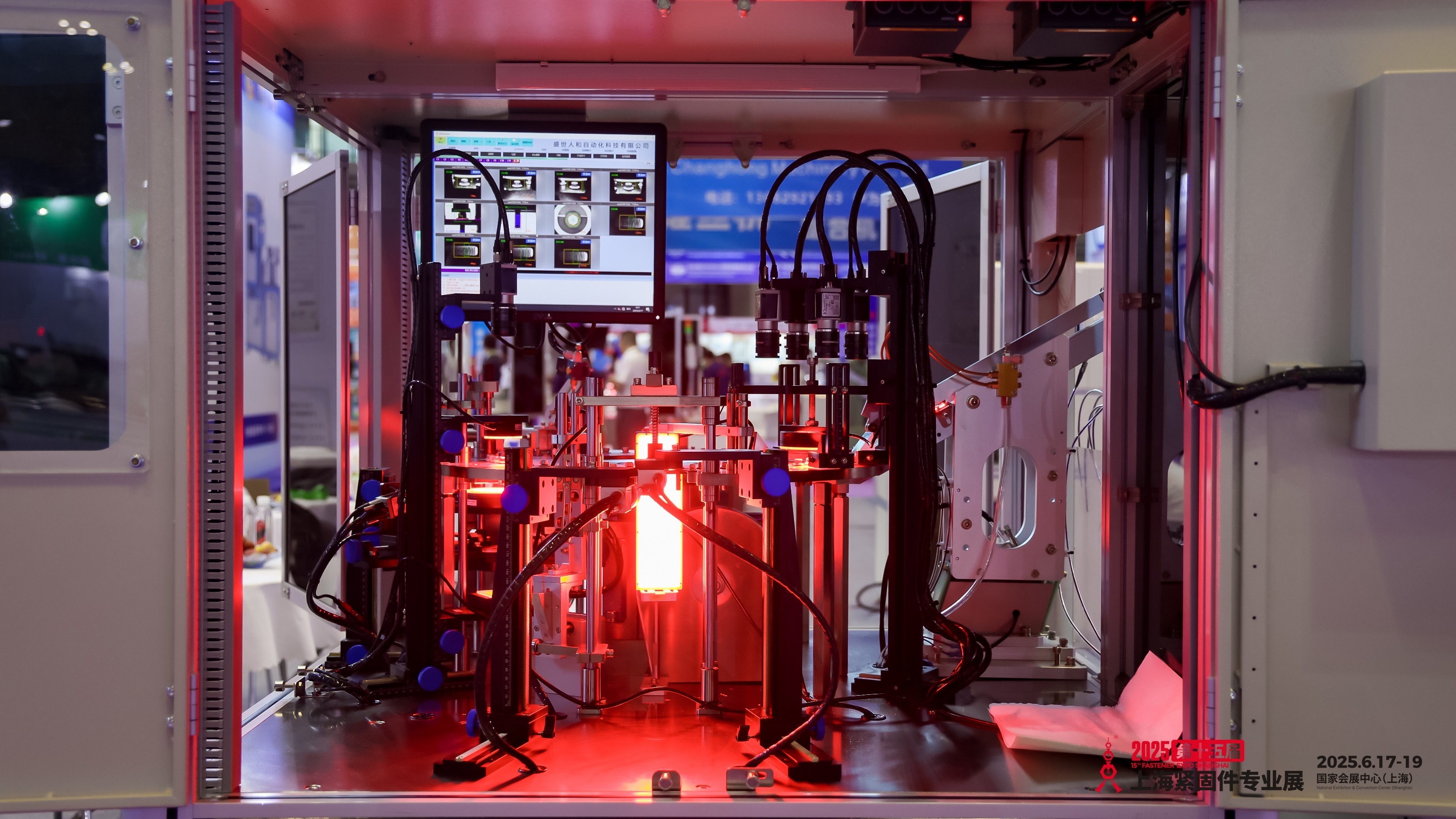

From a manufacturing perspective, process optimization has emerged as a key pathway for reducing emissions. Compared with traditional high-energy hot processing methods, cold heading and cold forming technologies offer clear advantages in improving material utilization and reducing waste. By minimizing material loss and lowering energy consumption during production, carbon emissions per unit can be effectively reduced. In parallel, the adoption of intelligent and automated production equipment allows for more precise energy management, providing a solid technical foundation for energy efficiency improvements.

At the material level, selection criteria within the fastener industry are also evolving. While strength grades and cost once dominated decision-making, factors such as carbon footprint, recyclability, and supply stability are increasingly being incorporated into material evaluation systems. Increasing the use of recycled steel and optimizing alloy compositions—while maintaining required performance levels—are becoming important directions for industry innovation. These material-level adjustments help reduce energy consumption in upstream processes and support the development of more sustainable supply chains.

From an application standpoint, fasteners also deliver tangible low-carbon value in downstream industries. As sectors such as new energy vehicles, rail transportation, wind power, and photovoltaics continue to expand, lightweight structures and high-efficiency designs are becoming increasingly important. High-performance fasteners help ensure reliable connections while reducing overall material usage, thereby lowering carbon emissions across the product life cycle. In equipment manufacturing, improved fastener reliability and durability can also reduce maintenance frequency and replacement cycles, further decreasing resource consumption during the operational phase.

Importantly, the low-carbon transformation of manufacturing cannot be achieved by individual companies alone—it requires coordinated efforts across the entire industrial value chain. In this process, industry platforms play an increasingly vital role. As a key global platform for the fastener industry, Fastener Expo Shanghai provides an essential venue for showcasing technological achievements, sharing transformation experience, and connecting with downstream applications. After fifteen successful editions, Fastener Expo Shanghai has become one of the world’s three leading fastener exhibitions and, in 2025, ranked as the largest fastener exhibition globally by exhibition area, setting benchmarks in scale, quality, and international influence.

Building on this foundation, Fastener Expo Shanghai 2026 will place even greater emphasis on the foundational role of fasteners within low-carbon manufacturing systems. By highlighting green materials, energy-efficient processes, and low-carbon manufacturing solutions, the exhibition will offer the industry practical and replicable transformation models. For fastener companies, the event is not only a platform to present products and technologies, but also a strategic opportunity to reassess development pathways and actively engage in the global low-carbon manufacturing transition.

As manufacturing moves toward higher-quality and more sustainable development, low carbon is no longer an optional add-on—it is a fundamental requirement. As an indispensable part of the industrial system, the fastener industry is contributing to the low-carbon revolution in manufacturing through continuous optimization of processes, materials, and applications—demonstrating how even the smallest components can make a meaningful impact on a greener industrial future.

Official Website: www.fastenerexpo.cn/en

Media Contact: Goblic Hu

Email: goblic.hu@ebseek.com

Phone: +86 138 1631 0340

Please first Loginlater ~